The 'zero watt' night lamp project was very popular, with many DIYers enthusiastically pursuing conversions. While on the subject of 'conversions', let us look at another idea that was triggered by the needs of the mother of a newborn.

As we all know, in India, one of the hot-selling items is the electric "mosquito repeller", or, to give it its proper name, the electric vaporizer for mosquito repellent. Every household has three or four--if not more-- of these units and most of them are kept on throughout the night. Most of these units consist of little more than a ceramic heater element and a neon tube or LED power-on indicator, the whole thing built into a plug-pack.

The lady in question, a brand new mother, wanted a dim night-lamp. The usual 'zero watter' was too bright for her liking and she said the mosquito unit's 'on' indicator was too dim to serve any useful purpose. This gave me the idea to replace the neon or the solitary red LED with a couple of hi-brite LEDs. Of course, we know that it is an easy matter to 'tailor' the brightness by choosing a suitable 'dropper' capacitor. I decided on a two-LED configuration in order to keep the assembly simple and at the same time make use of both negative and positive swings of the mains AC waveform. Just have a look at the circuit/s and the modifications.

First of all open up your mosquito unit--usually a couple of screws in the bottom secure the two halves of the shell together. Be careful to study the plug-pin unit and its mounting to the assembly while disassembling. You will see the ceramic heater and sometimes a 'protector' NTC device wired together directly to the plug pins. The neon or the LED too will be connected to the same points through a series resistor. Please note that the heater gets really hot and so soldered joints will not stay put, and the original connections will be twisted or crimped. Use a sharp cutter and cut away the indicator's series resistor, leaving a few mm of lead for us to 'twist-connect' to. Do the same thing at the other end too while cutting away the neon or the LED.

Now study the unit and plan how you are going to mount the LEDs. Usually they do not need any "mounting". You can follow the example shown and evolve your own method. I soldered together two LEDs back-to-back--that is joined them together with the + lead of one to the - lead of the other and the - lead of the first to the + lead of the second. This is how they looked, with one lead each left uncut for connection to the series resistor and the dropper cap/bleeder resistor combo, respectively.

This made it convenient to wedge the LED assembly to a vertical 'holder' moulding that originally held the neon indicator tube/LED. Check the photo for the details. This meant that ample insulation was also there between the leads and the LEDs faced up, throwing their light onto the ceiling. The diffuser of the unit does not "diffuse" the focussed LED beam that much, and I found that it was best to mount the LEDs facing up. You may try your own "trial and error" methods here for mounting/direction of the LEDs.

I chose a 0.1 uF/400V dropper capacitor and a 1k Ohm/half watt series resistor. After twisting and soldering the bleeder resistor onto the cap leads, check the "measurements" by placing the LED assembly, the cap etc into the shell and then cut the leads to give you enough to 'twist-mount' the parts. Crimp or twist one end of the dropper cap to the heater terminal lead stub (that you had left conveniently cut earlier). At the other heater terminal, crimp or twist-mount the 1 k Ohm resistor. Now mount the twin-LED assembly suitably and cut the leads so that you can comfortably twist the two ends of the LED assembly to the capcitor lead and the resistor lead on either side. The leads will be rigid enough to keep the assembly safely in position. Test by plugging in.

The LEDs should light up and the heater should heat up. Once everything is satisfactory, use minimum solder and solder up all the twisted connections to preclude oxidation of the twisted contacts over time. Reassemble the shells together carefully and you have a nice combo mosquito unit/night-lamp for the bed room or the child's room--or anywhere else you might want to have some dim 'romantic' lighting!

So get a couple of LEDs and resistors and a capacitor, and open up that mosquito unit -- ASAP!

* * * * * * * * * * * *

Easy Electronics DIY Projects

Jump aboard the DIY Xpress, the forum for easy electronics DIY projects.

Welcome to all my beloved "boys" (and that includes the girls too!) who enjoy doing things.

Together let us get our hands on things and make them better...

... and better-suited to each of us!

Wednesday, March 16, 2011

Monday, March 14, 2011

EASY 'ZERO WATT' SAVERS

That project title could easily qualify as an 'oxymoron'-- an expression with apparently contradictory terms/ ideas appearing together. But from our DIY angle in the Indian context, we are, I believe, justified fully! Read on to find out where the saving comes in and what the zero is about.

A recent "power audit" at my home and my sister's place sort of "opened my eyes". I came across many situations when the little drops would over time make up, if not an ocean, at least a fair-sized swimming pool or a large pond. I am sure your experience too may not be far from mine.

In many households it is a practice to keep small lamps burning continuously in the 'puja' room, surely before the pictures/icons of gods and goddesses, not to speak of the photos/paintings of our long-departed beloved relatives. Usually the choice here falls on small coloured bulbs. Another common practice is to have a small night lamp burning throughout the night in bedrooms, particularly those of children. Here also the choice is mostly small bulbs. These bulbs are usually referred to as "zero watt" bulbs as their consumption is "ridiculously low", according to the makers and the shopwallahs.

This might have been so in the good old days of the analogue electricity meter, which needed some healthy current flowing thorugh it to start it running. Not so now in these days of the electronic utility meter that registers even minuscule amounts of current. I checked a number of "zero watt" bulbs and found that ALL of them consumed between 3 and 5 Watts! So a few "zero watt" bulbs burning throughout or at least through the night would, at the end of the second month when the electricity meter reader comes, easily add up to a few units-- one 5 W bulb running for about eight days or about 16 nights would 'eat up' one unit of power.

This, then, was the trigger for me to try something new to save some of those "zero watts". By now I am sure most of us have become adept at using LEDs wherever low-light applications are called for. Nobody is going to stop you from taking a few LEDs and wiring them up as a "zero watt" bulb replacement or as a night-lamp, following our 'standard' circuit. But that is all old hat! So here let us take a look at an EASY, NOVEL solution with a minimum parts count too.

A look at our 'standard circuit' reveals the dropper cap and bleeder resistor, the bridge rectifier and the LEDs and their current limiter resistors. When we used the ready-made LED strips, the strip contained the current-limiting resistors too. As this is a low-light application, we will use smaller values for the dropper cap, and use just a few hi-brite LEDs.

Hey, hey, aren't LEDs Light Emitting DIODEs? That gives us a novel idea! Throw out the bridge rectifier diodes and use four LEDs instead, and use one or two more LEDs as the "load"! That should give us five or six LEDs and enough light as a "zero watter" or as a night-lamp.

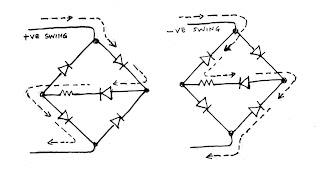

The AC mains gives us alternating current which from zero rises to a peak and then falls to zero and goes to a negative peak, then back to zero, with the peak voltage going up to about 1.4 times the average value of 230 Volts. Looking at the bridge rectifier, we can easily see that on positive cycles current flows thorugh one leg of the bridge to the 'load', and completes the circuit through the other leg of the bridge. On negative swings, it is the other two legs and the 'load' that conduct the current. Just follow the arrows on the diagrams below and things will be clear to you.

This means that with an all-LED setup, on positive swings, two diodes of the bridge legs will be lit, along with the 'load' LED; on negative swings, the other two LEDs of the bridge and the 'load' LED will be lit. That is to say, the 'load' LED will be lit continuously (I am ignoring the pulsed drive here --not DC--for simplicity), while 'one half of the bridge' will "flicker on" only when those diodes conduct. In practice this is not going to make much of difference as the 'load' LED will be brighter and will keep the average light at a higher level so that you don't notice the flicker. If you look through a digital camera, its CMOS sensor will make the flicker easier to see.

I have redrawn the circuit so that it resembles the physical layout, and the photo shows the wired-up version with just one 'load' LED. Be sure to watch the LED polarities as you have to be careful to get it right. Again, check the drawings. The 'load' may be one, two or three LEDs depending on your brightness requirements. Also, "fine tune" the value of the dropper cap, beginning with a 0.22 uF/400V one, as otherwise the lamp is likely to be too bright.

It will be a cinch to wire up "self-supporting" LED arrays and put them into night-lamp mouldings and into decorative plastic fittings to make "zero watters". Be sure to use small lengths of plastic sleeving over bare leads of LEDs etc and pay attention to insulation and safety while "playing with" mains voltages.

Let us 'zero in' on those zero watters!

* * * * * * * * * * * *

A recent "power audit" at my home and my sister's place sort of "opened my eyes". I came across many situations when the little drops would over time make up, if not an ocean, at least a fair-sized swimming pool or a large pond. I am sure your experience too may not be far from mine.

In many households it is a practice to keep small lamps burning continuously in the 'puja' room, surely before the pictures/icons of gods and goddesses, not to speak of the photos/paintings of our long-departed beloved relatives. Usually the choice here falls on small coloured bulbs. Another common practice is to have a small night lamp burning throughout the night in bedrooms, particularly those of children. Here also the choice is mostly small bulbs. These bulbs are usually referred to as "zero watt" bulbs as their consumption is "ridiculously low", according to the makers and the shopwallahs.

This might have been so in the good old days of the analogue electricity meter, which needed some healthy current flowing thorugh it to start it running. Not so now in these days of the electronic utility meter that registers even minuscule amounts of current. I checked a number of "zero watt" bulbs and found that ALL of them consumed between 3 and 5 Watts! So a few "zero watt" bulbs burning throughout or at least through the night would, at the end of the second month when the electricity meter reader comes, easily add up to a few units-- one 5 W bulb running for about eight days or about 16 nights would 'eat up' one unit of power.

This, then, was the trigger for me to try something new to save some of those "zero watts". By now I am sure most of us have become adept at using LEDs wherever low-light applications are called for. Nobody is going to stop you from taking a few LEDs and wiring them up as a "zero watt" bulb replacement or as a night-lamp, following our 'standard' circuit. But that is all old hat! So here let us take a look at an EASY, NOVEL solution with a minimum parts count too.

A look at our 'standard circuit' reveals the dropper cap and bleeder resistor, the bridge rectifier and the LEDs and their current limiter resistors. When we used the ready-made LED strips, the strip contained the current-limiting resistors too. As this is a low-light application, we will use smaller values for the dropper cap, and use just a few hi-brite LEDs.

Hey, hey, aren't LEDs Light Emitting DIODEs? That gives us a novel idea! Throw out the bridge rectifier diodes and use four LEDs instead, and use one or two more LEDs as the "load"! That should give us five or six LEDs and enough light as a "zero watter" or as a night-lamp.

The AC mains gives us alternating current which from zero rises to a peak and then falls to zero and goes to a negative peak, then back to zero, with the peak voltage going up to about 1.4 times the average value of 230 Volts. Looking at the bridge rectifier, we can easily see that on positive cycles current flows thorugh one leg of the bridge to the 'load', and completes the circuit through the other leg of the bridge. On negative swings, it is the other two legs and the 'load' that conduct the current. Just follow the arrows on the diagrams below and things will be clear to you.

This means that with an all-LED setup, on positive swings, two diodes of the bridge legs will be lit, along with the 'load' LED; on negative swings, the other two LEDs of the bridge and the 'load' LED will be lit. That is to say, the 'load' LED will be lit continuously (I am ignoring the pulsed drive here --not DC--for simplicity), while 'one half of the bridge' will "flicker on" only when those diodes conduct. In practice this is not going to make much of difference as the 'load' LED will be brighter and will keep the average light at a higher level so that you don't notice the flicker. If you look through a digital camera, its CMOS sensor will make the flicker easier to see.

I have redrawn the circuit so that it resembles the physical layout, and the photo shows the wired-up version with just one 'load' LED. Be sure to watch the LED polarities as you have to be careful to get it right. Again, check the drawings. The 'load' may be one, two or three LEDs depending on your brightness requirements. Also, "fine tune" the value of the dropper cap, beginning with a 0.22 uF/400V one, as otherwise the lamp is likely to be too bright.

It will be a cinch to wire up "self-supporting" LED arrays and put them into night-lamp mouldings and into decorative plastic fittings to make "zero watters". Be sure to use small lengths of plastic sleeving over bare leads of LEDs etc and pay attention to insulation and safety while "playing with" mains voltages.

Let us 'zero in' on those zero watters!

* * * * * * * * * * * *

Thursday, March 10, 2011

EASY LED 'BULB'

I can see a lot of eyebrows going up on seeing the title of the project.

Aren't bulbs passe?

Sure, they are; but...

The recent International and National campaigns to replace the incandescent bulb with a more energy-efficient alternative is fresh in our minds. The good old electric bulb has been with us all along right from the days of Edison, the original inventor of the incandescent bulb. Over the decades it had held its own--it was simple, inexpensive and universal. Only that it was not energy efficient, especially when compared to fluoresent tubes and their smaller cousins, the CFLs. Today it is not easy to locate a bulb in an average household as a result of the 'replace the bulb' campaign.

Looking forward to the future, we can easily see that it is the era of the LED, which is even more efficient than the bulb and the CFL, its life is phenomenally longer and it runs cooler, it can work at very low voltages directly, and overall it is more reliable. Then why haven't LED lamps replaced the bulbs and the CFLs? High cost is the factor that has kept the LED lamps from being very popular.

A look at the local market reveals that 'drop-in' LED replacements for the bulb are available, but they are pricey, Indian ones going for about Rs 700 plus and cheaper Chinese imports going for about Rs 300 and up. And frankly, many of them are not bright enough, nor are their 'beam patterns' suitable for replacement in standard lamp shades. The right time for the DIY guy to try his hand.

Here is an LED 'bulb' that is inexpensive and works in most common lamp shades as the LEDs are deployed in 360 degrees. Above all, like most of our projects, this is EASY! In fact it is one of the easiest and cheapest of projects, as a 1 metre strip of LEDs and a few components are the only things you need to purchase.

HANDS-ON

Retrieve an old fused CFL from the junk box. Disassemble it and discard the glass tube part carefully. Unsolder the leads from the bayonet holder to the small PCB. You will see a bridge rectifier (four mains-rated diodes) right where the AC goes in. Either remove the diodes, or better, remove all the other components and retain the bridge on the small round PCB. Refer to our strip-lamp circuit and connect the 0.47 uF cap + bleeder resistor to one side of the bridge. The free end of the "dropper cap" can be wired to any small PCB pad and now you can wire up one of the AC mains inputs from the bayonet holder to that pad and the other AC wire from the bayonet socket to the other corner of the bridge. Remember, there is no switch here. Wire up a black and red wire each to the + and - outputs of the bridge to feed the LED strip.

Now look around in your junk box (or ask your friendly plumber!) for a suitable diameter PVC water pipe that fits into the top part of the CFL housing. Wind the LED strip around this in a spiral and note how long a piece you would need. Refer to the pics and finalize your assembly. I have used a couple of screws so that it can be disassembled easily for trying various caps etc. Once you have tested and finalized everything, the best deal would be to use hot-melt glue and stick it together. A small hole is drilled through which the +/- wires are fed and soldered to the strip. It is better to solder the leads before sticking the LED strip down. Do it fast with pre- tinned leads and take care not to overheat and melt the strip into goo! Now mark the first spiral with a scratch on the PVC pipe.

Now clean the PVC pipe with detergent and dry it thoroughly, and see that you don't get grease on it by touching it. Remove a few inches of the adhesive backing paper from the LED strip and carefully align the first spiral to the mark made earlier and begin sticking down the strip. As you go, continue to remove the backing paper and carefully stick the rest of the strip to the PVC pipe. See that this is where your "artistry" has to come into play! You will be amazed to see the whole 1 metre of the strip occupying a length of hardly 3 inches of pipe. Put a small glob of hot-melt glue at the end of the strip and seal the small hole for the wires at the other end too.

Connect up everything, either screw together or better glue together the byonet holder part and the PVC pipe section, seal the bottom of the pipe with a disc of plastic or laminate or even thermocol to keep out the pests. Remember to drill a few small holes in the disc, which, along with the holes in the base of the holder, assures some ventilation for the circuit. That is all!

Push it into a lamp shade, and switch on, and you have got onto the Energy Star bandwaggon with a state-of-the-art LED 'bulb' !!

Build as many as you want for your low-light needs and surely you will save some money and also reap a lot of satisfaction. In case you want a longer 'bulb', it is only an easy matter to add another half a metre or even one more metre of strip and use a suitably longer pvc pipe. If you want a stouter bulb, use a larger diameter pipe and use a "reducer" available from plumbing suppliers and glue the holder part at the end of the "reducer". This will make it easier to have a couple of metres of LED strip on a short and stout piece of pipe. As I said earlier, your imagination would suggest many more designs to you to meet your varied needs.

Now's the time to replace those bulbs with better 'bulbs' !!

* * * * * * * * * * * *

Aren't bulbs passe?

Sure, they are; but...

The recent International and National campaigns to replace the incandescent bulb with a more energy-efficient alternative is fresh in our minds. The good old electric bulb has been with us all along right from the days of Edison, the original inventor of the incandescent bulb. Over the decades it had held its own--it was simple, inexpensive and universal. Only that it was not energy efficient, especially when compared to fluoresent tubes and their smaller cousins, the CFLs. Today it is not easy to locate a bulb in an average household as a result of the 'replace the bulb' campaign.

Looking forward to the future, we can easily see that it is the era of the LED, which is even more efficient than the bulb and the CFL, its life is phenomenally longer and it runs cooler, it can work at very low voltages directly, and overall it is more reliable. Then why haven't LED lamps replaced the bulbs and the CFLs? High cost is the factor that has kept the LED lamps from being very popular.

A look at the local market reveals that 'drop-in' LED replacements for the bulb are available, but they are pricey, Indian ones going for about Rs 700 plus and cheaper Chinese imports going for about Rs 300 and up. And frankly, many of them are not bright enough, nor are their 'beam patterns' suitable for replacement in standard lamp shades. The right time for the DIY guy to try his hand.

Here is an LED 'bulb' that is inexpensive and works in most common lamp shades as the LEDs are deployed in 360 degrees. Above all, like most of our projects, this is EASY! In fact it is one of the easiest and cheapest of projects, as a 1 metre strip of LEDs and a few components are the only things you need to purchase.

HANDS-ON

Retrieve an old fused CFL from the junk box. Disassemble it and discard the glass tube part carefully. Unsolder the leads from the bayonet holder to the small PCB. You will see a bridge rectifier (four mains-rated diodes) right where the AC goes in. Either remove the diodes, or better, remove all the other components and retain the bridge on the small round PCB. Refer to our strip-lamp circuit and connect the 0.47 uF cap + bleeder resistor to one side of the bridge. The free end of the "dropper cap" can be wired to any small PCB pad and now you can wire up one of the AC mains inputs from the bayonet holder to that pad and the other AC wire from the bayonet socket to the other corner of the bridge. Remember, there is no switch here. Wire up a black and red wire each to the + and - outputs of the bridge to feed the LED strip.

Now look around in your junk box (or ask your friendly plumber!) for a suitable diameter PVC water pipe that fits into the top part of the CFL housing. Wind the LED strip around this in a spiral and note how long a piece you would need. Refer to the pics and finalize your assembly. I have used a couple of screws so that it can be disassembled easily for trying various caps etc. Once you have tested and finalized everything, the best deal would be to use hot-melt glue and stick it together. A small hole is drilled through which the +/- wires are fed and soldered to the strip. It is better to solder the leads before sticking the LED strip down. Do it fast with pre- tinned leads and take care not to overheat and melt the strip into goo! Now mark the first spiral with a scratch on the PVC pipe.

Now clean the PVC pipe with detergent and dry it thoroughly, and see that you don't get grease on it by touching it. Remove a few inches of the adhesive backing paper from the LED strip and carefully align the first spiral to the mark made earlier and begin sticking down the strip. As you go, continue to remove the backing paper and carefully stick the rest of the strip to the PVC pipe. See that this is where your "artistry" has to come into play! You will be amazed to see the whole 1 metre of the strip occupying a length of hardly 3 inches of pipe. Put a small glob of hot-melt glue at the end of the strip and seal the small hole for the wires at the other end too.

Connect up everything, either screw together or better glue together the byonet holder part and the PVC pipe section, seal the bottom of the pipe with a disc of plastic or laminate or even thermocol to keep out the pests. Remember to drill a few small holes in the disc, which, along with the holes in the base of the holder, assures some ventilation for the circuit. That is all!

Push it into a lamp shade, and switch on, and you have got onto the Energy Star bandwaggon with a state-of-the-art LED 'bulb' !!

Build as many as you want for your low-light needs and surely you will save some money and also reap a lot of satisfaction. In case you want a longer 'bulb', it is only an easy matter to add another half a metre or even one more metre of strip and use a suitably longer pvc pipe. If you want a stouter bulb, use a larger diameter pipe and use a "reducer" available from plumbing suppliers and glue the holder part at the end of the "reducer". This will make it easier to have a couple of metres of LED strip on a short and stout piece of pipe. As I said earlier, your imagination would suggest many more designs to you to meet your varied needs.

Now's the time to replace those bulbs with better 'bulbs' !!

* * * * * * * * * * * *

Wednesday, March 2, 2011

EASY DISCRETE-LED MOUNTS

Once an idea is mooted, the "boys" want proof of concept! Thank you for your enthusiasm.

Here is a small assortment of discrete-LED mounts adapted for commercial lamps and fittings.

The first is a personal favourite. An old CFL table-lamp had reluctantly been consigned to the 'junk box'. It was retrieved, cleaned up and the insides removed. I retained the old heavy choke or ballast purely as "ballast" to keep the lamp steady with its weight. A small piece of parallel-track PCB was cut and fashioned to fit into the lamp housing and the LEDs and resistors were wired up. The original switch was retained and the capacitor/bridge rectifier assembly was kept in the base and insulated well from the heavy iron and copper ballast. As the lamp "joints" move a lot while the lamp height is adjusted, good quality thin two-core jacketed mains wire was used for connection from the bridge to the LED PCB. Screw everything back together and you have that favourite old lamp in a new energy-efficient and cool-running 'avatar'! The technique could be adapted to modify virtually any table lamp that you have.

The second is a 'dome light' at home that stays switched on from evening till midnight, which makes it a prime candidate for LED conversion. The photo shows the acrylic LED mount and the glass dome diffuser. As it needs to put out a 'decent' amount of light, LEDs were 'lavished' on it. A piece of acrylic, cut to fit inside the housing is marked and drilled for the LEDs. It is best to do all your planning and drawing on a piece of graph paper to make it easy. Then stick the paper to the acrylic sheet with glue (it will peel off easily) and then drill it carefully. The photo shows an early 'proto' sheet that broke while drilling. If your lamp assembly is small, you could even use a couple of waste CDs (perhaps DVDs will be more 'mod'!) stuck together with superglue for thickness and strength as the LED base. (A good gesture from the angle of recycling too! ) Be careful, as always, about clean wiring and soldering and insulation. Mount the assembly into the lamp and wire it to the domestic wiring using a 2X screw connector strip. Put on the glass dome, and the diffuser will give a smooth spread of light.

The third project tackles the conversion of a tubular hanging lamp with a spotted glass cylindrical shade. This called for a tubular mount for the LEDs. A short piece of 2 inch PVC water pipe does duty nicely here. The pipe is split in the middle into two so that the LEDs could be wired up easily. The two halves are wired up and tested as independent lamp assemblies and after rolling up a piece of plastic sheet (from an old file or so) as an insulator, the halves are joined together with tape or a couple of rings of plastic pipe that have been heated and pressed on. Remove the 'bayonet' fitting from a discarded CFL, connect up the wires and stick it to one end so that you could put the LED 'bulb' on just like a regular bulb or CFL into the lamp fitting.

Hope this gives you enough ideas to trigger your imagination. As I said, your imagination is the limit, and your care and craftsmanship will give a 'pro' finish to your handiwork, turning it into a "designer lamp". Remember to mail me your notes and pics so that I could post them here.

Gentlemen, start your drills!

* * * * * * * * * * * *

Here is a small assortment of discrete-LED mounts adapted for commercial lamps and fittings.

The first is a personal favourite. An old CFL table-lamp had reluctantly been consigned to the 'junk box'. It was retrieved, cleaned up and the insides removed. I retained the old heavy choke or ballast purely as "ballast" to keep the lamp steady with its weight. A small piece of parallel-track PCB was cut and fashioned to fit into the lamp housing and the LEDs and resistors were wired up. The original switch was retained and the capacitor/bridge rectifier assembly was kept in the base and insulated well from the heavy iron and copper ballast. As the lamp "joints" move a lot while the lamp height is adjusted, good quality thin two-core jacketed mains wire was used for connection from the bridge to the LED PCB. Screw everything back together and you have that favourite old lamp in a new energy-efficient and cool-running 'avatar'! The technique could be adapted to modify virtually any table lamp that you have.

The second is a 'dome light' at home that stays switched on from evening till midnight, which makes it a prime candidate for LED conversion. The photo shows the acrylic LED mount and the glass dome diffuser. As it needs to put out a 'decent' amount of light, LEDs were 'lavished' on it. A piece of acrylic, cut to fit inside the housing is marked and drilled for the LEDs. It is best to do all your planning and drawing on a piece of graph paper to make it easy. Then stick the paper to the acrylic sheet with glue (it will peel off easily) and then drill it carefully. The photo shows an early 'proto' sheet that broke while drilling. If your lamp assembly is small, you could even use a couple of waste CDs (perhaps DVDs will be more 'mod'!) stuck together with superglue for thickness and strength as the LED base. (A good gesture from the angle of recycling too! ) Be careful, as always, about clean wiring and soldering and insulation. Mount the assembly into the lamp and wire it to the domestic wiring using a 2X screw connector strip. Put on the glass dome, and the diffuser will give a smooth spread of light.

The third project tackles the conversion of a tubular hanging lamp with a spotted glass cylindrical shade. This called for a tubular mount for the LEDs. A short piece of 2 inch PVC water pipe does duty nicely here. The pipe is split in the middle into two so that the LEDs could be wired up easily. The two halves are wired up and tested as independent lamp assemblies and after rolling up a piece of plastic sheet (from an old file or so) as an insulator, the halves are joined together with tape or a couple of rings of plastic pipe that have been heated and pressed on. Remove the 'bayonet' fitting from a discarded CFL, connect up the wires and stick it to one end so that you could put the LED 'bulb' on just like a regular bulb or CFL into the lamp fitting.

Hope this gives you enough ideas to trigger your imagination. As I said, your imagination is the limit, and your care and craftsmanship will give a 'pro' finish to your handiwork, turning it into a "designer lamp". Remember to mail me your notes and pics so that I could post them here.

Gentlemen, start your drills!

* * * * * * * * * * * *

Subscribe to:

Posts (Atom)